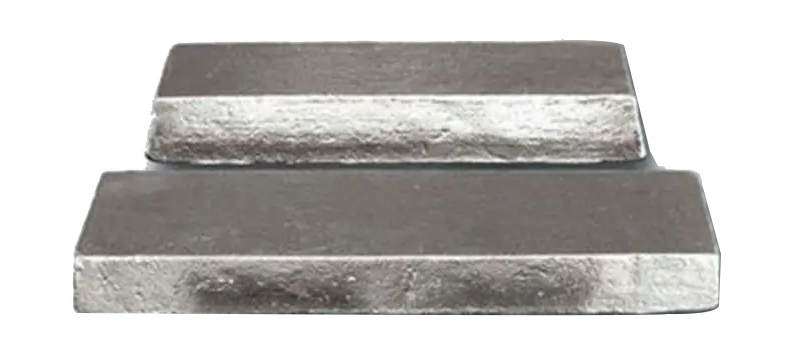

Magnesium Ingot

Introduce:

Magnesium ingots are melted in a die-casting machine and cast into primary products of various shapes, and then through a series of subsequent processing, they can be made into exquisite products.

Characteristics:

1. The density of high-purity magnesium ingot is small, 1/3 lighter than that of aluminum, and its specific strength is higher than that of aluminum alloy.

2. The fatigue limit of high-purity magnesium ingots is very high, which is larger than the impact load of aluminum alloys.

3. High-purity magnesium ingots have good thermal conductivity and good casting properties.

4. High-purity magnesium ingots have good dimensional stability and are easy to recycle.

5. High-purity magnesium ingot has good machinability and good vibration damping performance.

6. High-purity magnesium ingots are superior to engineering plastics in many aspects and can replace engineering plastics.

7. Lightweight and Recyclable

Technical Data Sheet:

| Standard | Chemical composition (%) | ||||||||

| Mg ≥ | Al | Mn | Si | Fe | Cl | Cu | Ni | other | |

| mg9980 | 99.8 | 0.05 | 0.05 | 0.03 | 0.05 | 0.005 | 0.02 | 0.002 | 0.05 |

| mg9990 | 99.9 | 0.02 | 0.03 | 0.02 | 0.04 | 0.005 | 0.004 | 0.001 | 0.01 |

| mg9995 | 99.95 | 0.01 | 0.01 | 0.01 | 0.003 | 0.003 | 0.002 | 0.001 | 0.005 |

| mg9998 | 99.98 | 0.004 | 0.002 | 0.003 | 0.002 | 0.002 | 0.0005 | 0.0005 | 0.005 |

| mg9999 | 99.99 | 0.003 | 0.001 | 0.002 | 0.002 | 0.002 | 0.001 | 0.001 | 0.005 |

Picture Display:

Application:

Magnesium ingots are mainly used to make magnesium alloys. At present, the most widely used magnesium alloys are magnesium-aluminum alloys, followed by magnesium-manganese alloys and magnesium-zinc-zirconium alloys. Mainly used in aviation, aerospace, transportation, chemical, rocket and other industrial sectors.

Packaging&Shipping:

In order to better ensure the safety of our goods, we will provide professional, environmentally friendly, convenient and efficient packaging services and transportation.